Our Services

What we offer

Project Management

Solutioneering, in its commitment to project management principles, has successfully overseen various projects across different sectors. These projects include:

Demolition: Efficiently managing the removal of structures or facilities.

Engine Room Construction: Ensuring the construction of engine rooms meets project objectives.

Infrastructure: Handling infrastructure development projects.

Primary Industry Factory Installs: Facilitating the installation of factories in the primary industry sector.

By adhering to project management principles, Solutioneering has achieved positive outcomes in these diverse areas.

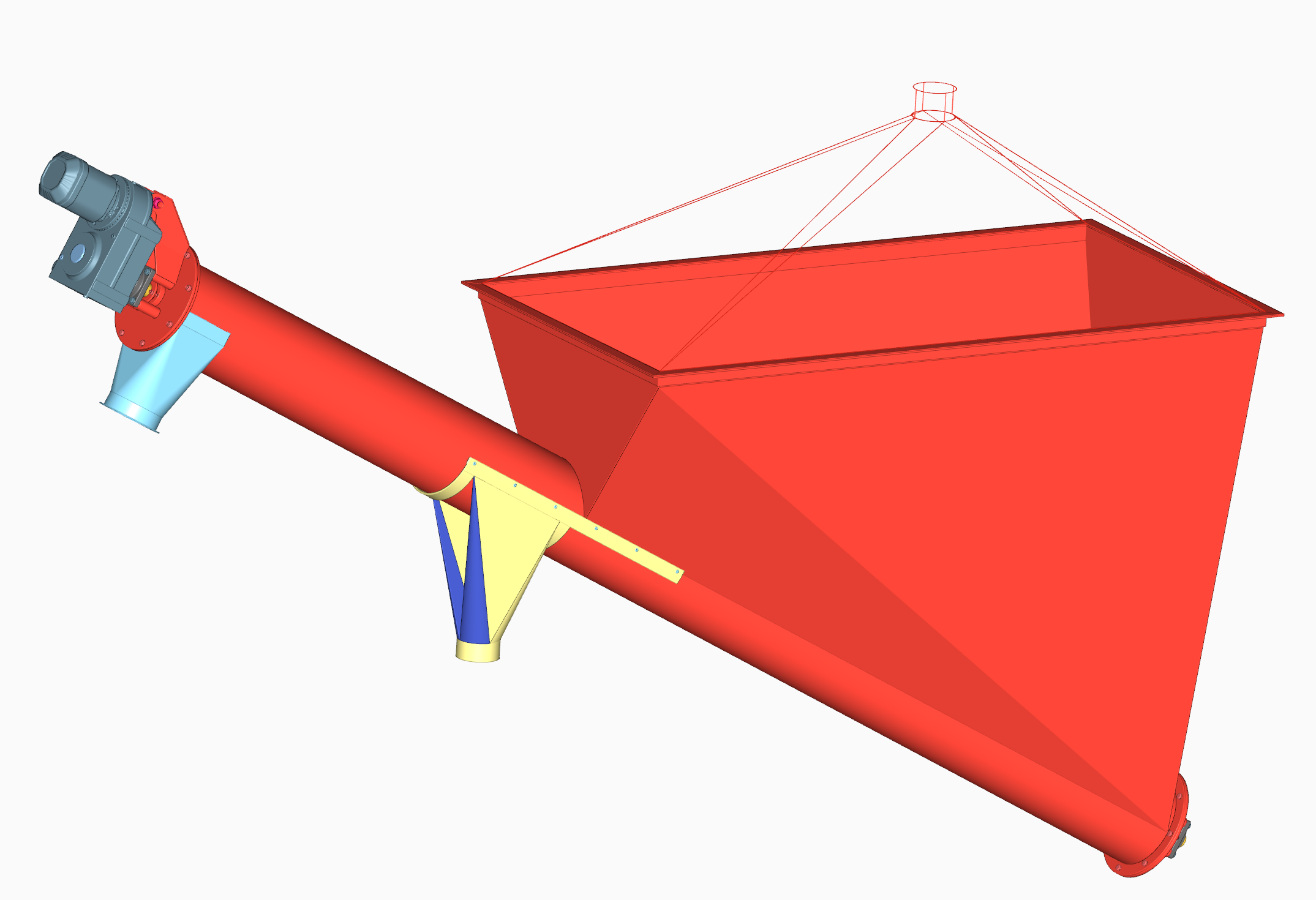

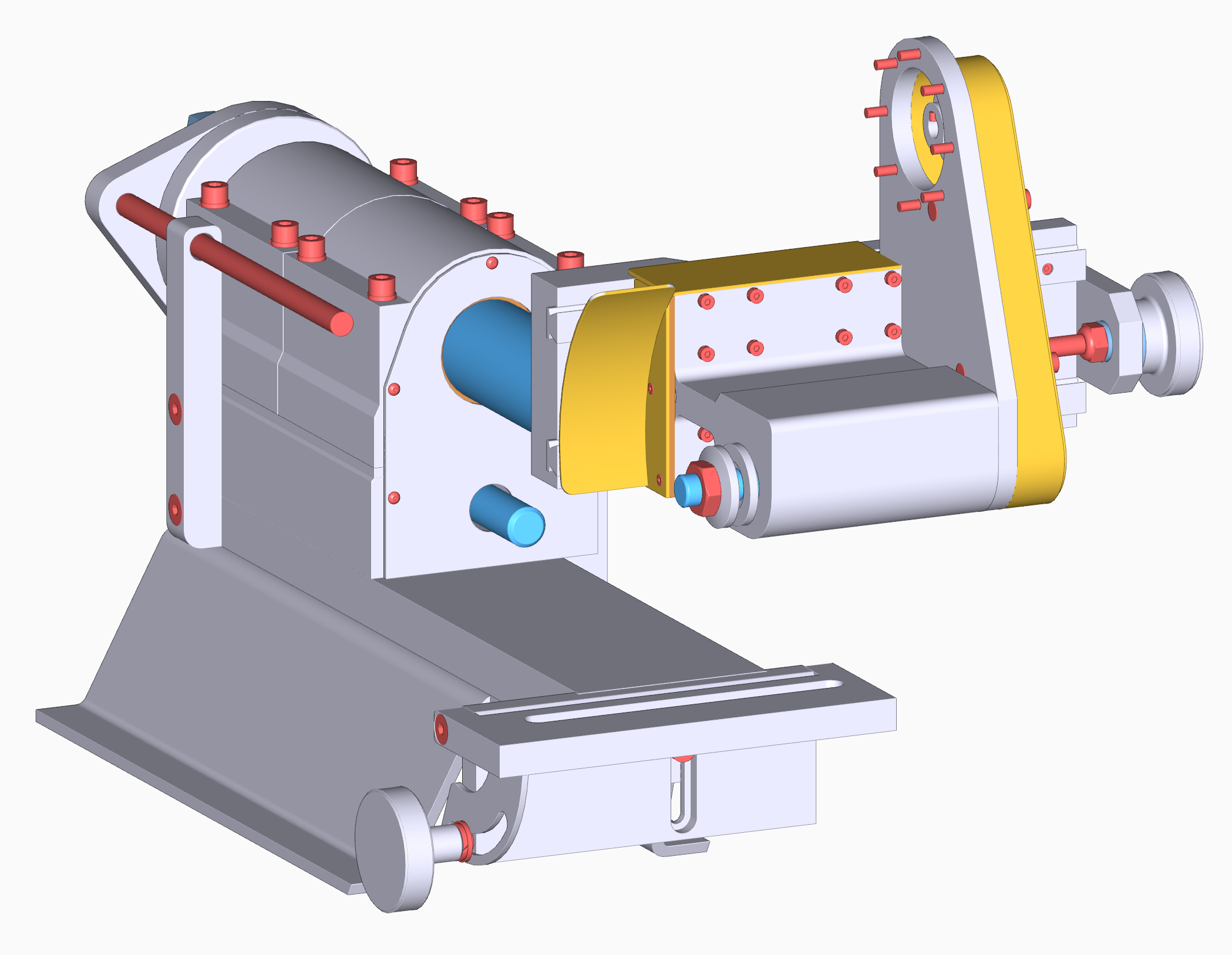

Mechanical Install

Solutioneering offers an End-to-End Machinery Risk Install Management Approach that caters to industry-specific needs. Here’s what it entails:

Existing Machinery Assessments and Upgrades: Solutioneering evaluates and enhances existing machinery to ensure safety and efficiency.

Replacements: When machinery needs replacement, Solutioneering manages the entire process, from selection to installation.

Full Process Line Design: Solutioneering designs comprehensive process lines, considering safety and functionality.

By adhering to best practices and thorough risk assessments, Solutioneering ensures a safe and effective machinery setup for your team.

3D Printing & Prototyping

Solutioneering offers a cost-effective approach to prototyping. Their End-to-End design suite covers everything from 3D modeling to 3D printing and CNC file exchange. This seamless process allows design concepts to evolve into prototypes, with customers maintaining full control over the final solution.

Notably, Solutioneering is experienced in using lost PLA casting techniques. This method optimizes productivity and enables the realization of concepts, casting them in various alloys efficiently and cost-effectively.

CAD Services

Solutioneering, with over 25 years of industry experience, employs AutoCAD, a powerful computer-aided design (CAD) software. Here’s how Solutioneering utilizes AutoCAD for various tasks:

Concepts and Workshop Detailing: Solutioneering creates detailed 3D and 2D designs using AutoCAD, ensuring precision and accuracy.

Factory Layouts: AutoCAD helps design efficient factory layouts, optimizing space and workflow.

Site Layouts: Solutioneering uses AutoCAD to plan and visualize site layouts effectively.

Services P&ID’s: AutoCAD aids in creating Process and Instrumentation Diagrams (P&ID’s) for services.

Equipment Design, Fabrication, and Installation: AutoCAD supports the entire lifecycle of equipment, from design to fabrication and installation.

Drafting Services: Solutioneering produces technical drawings and documentation using AutoCAD.

Shop Drawings: AutoCAD generates detailed shop drawings for construction and manufacturing.

By leveraging AutoCAD’s capabilities, Solutioneering ensures precise and efficient project development.

The Results

Geraldine High School Gym project

The construction project, led by contractor Thompson Construction and Engineering (Thompson) and project managed by Solutioneering, “embodies a commitment to innovation and efficiency”, Cooper said.

“We are privileged to collaborate with Thompson Construction and Solutioneering on this project.

“Their dedication to excellence and community-driven approach aligns perfectly with our vision for the new gymnasium.” - STUFF